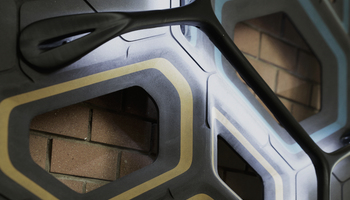

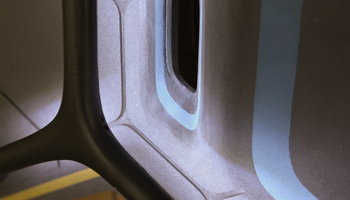

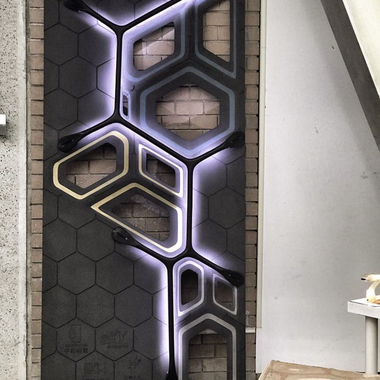

The Hexapod project is a computationally defined wall lighting system derived from subdivided mesh geometry and 3D printed demonstrating it’s direct to fabrication potential. The proposed installation is the product of the integration of both additive and subtractive manufacturing processes. While additive manufacturing and 3D printed solutions are not commonly found in final design products, the Hexapod 3D printed components utilize Modex ABS 3D printing filaments which offer excellent post-processing potential. The metallic finish is a five stage process in which the 3D printed parts are sanded, contoured, primed, electroplated and polished to create a suitable end product material solution. For the bench and wall surfaces CNC milled panels made of composite layers of the Valchromat engineered colored MDF board were selected for their smooth milling finishes and colors. The addition of color layers, patterning, and milled geometry result in the emergent expression of the subtractive design method