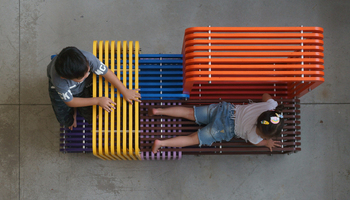

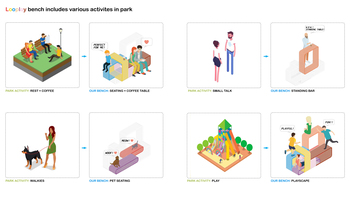

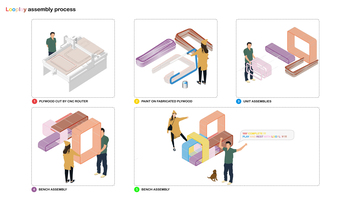

The project title is LOOPLAY, which is the compound word from the Loop and Play. Our design focuses on sitting motion on a public bench as a play (game) in a city or a park. We wanted to show that the street-seat could use as a place to rest but also where various activities can take place in an urban context. The loop form envisions a space for relaxation and playful space. Layering a variety of loop allows all ages of people to sit, lie down, and crawl in and out. It offers a sense of play while maintaining a connection to the surrounding environment. This bench’s playful transformation enables the public space to enliven the streetscape. We reinterpreted the conventional public bench having only seating function and proposed new bench design typology, which can invite communities and various activities. We focused on introducing a new typological seat containing multiple urban events to enhance the vibrancy of the downtown area after researching public activities around the site. This street bench is made up of SEVEN LOOPS, each of which already designed as a seating surface. There are different seating heights and orientations for adults, kids, and pets, all built into one bench. The seating levels are relative and spatially perceived differently according to one’s position, where people can be seated together or separately. The design will stand out in any environment by its atypical form and vibrant colors. The sitting experience on this unique bench will give the public a fun and exciting memories. As cities become increasingly dense, we focused on developing urban space infusing both civic identity and cultural celebration. The LOOPLAY offers playful seating for 2-6 people and is made up of 61 plywood components that are joined using layers of two connection systems – halved joints and rod/ nuts joints. Prefabrication is more economical and sustainable than traditional builds. Plywood components are cut to shape with a CNC router, paint vibrant colors, and will be shipped to the site to assemble. The assembly requires three main components; plywood, threaded steel rod, and nuts, and washers. Our design does not use chemical glue. It is easy to fabricate by intersecting with sectioning plywood components using halved joint and threaded spacer.