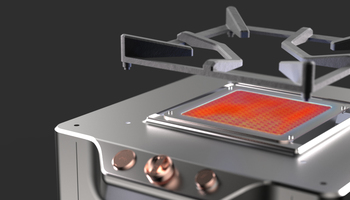

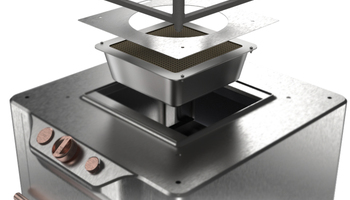

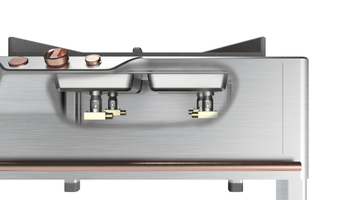

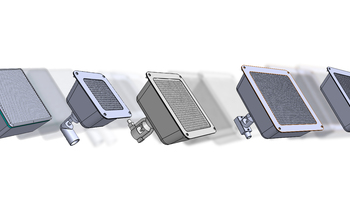

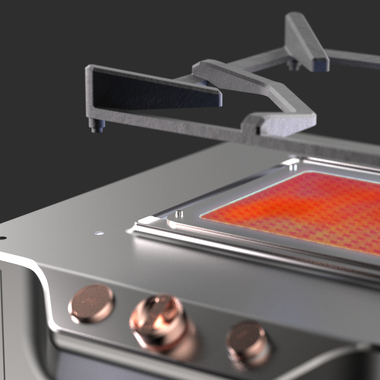

Who is Agnisumukh? Agnisumukh is an award winning startup entity in the area of Clean Green Energy efficient heat applications on gas fuel systems. Their overview is to provide Clean & Green Energy Efficient Heating Solutions, across all gas based fuels. Their R&D team has strategically partnered on joint research programs with the LPG Equipment Research Centre, a joint undertaking of Oil majors in India. What did we do for them? Agnisumukh approached us with their raw, nascent and innovative burner technology. It promised LPG savings of over 30%, a thermal efficiency of 69% and 0 carbon soot emission. These amongst other benefits of their technology were handed to us in the form of a crude prototype that was still successful and revolutionary. Agnisumukh employs a method of heat transfer known as radiant heat, this method of heating/cooking is on the same levels as that of heat produced by charcoal. They has already implemented these burners into all forms and applications of kitchen equipment, ranging from cooking ranges to bratt pans to hot plates. Effectively creating an ecosystem of products that ran cleaner and greener as compared to regular blue flame burners. The needs of the Indian kitchens are vast, ranging from small to large kitchen sizes and the ability to cater to all kinds of Indian cuisine. This caused problems for Agnisumukh as they found themselves creating custom sized burners and equipment to solve the needs of their customers. Manufacturing was labor intensive and time consuming, not to mention expensive as a result. The challenges posed to us were thus- How can we streamline manufacturing, installation and scalability in their ecosystem of kitchen equipment. Research and Execution We spent a vast amount of time in the kitchen where pilot runs of the burner were conducted. We understood that the delicate ceramic surface was prone to breakage and yet any protection would hamper their efficiency. The prototype was heavy and difficult to service every time because of a lot of secondary operations. In order to cut service time the entire burner was replaced instead of just the plate increasing costs. Burners occasionally had to be completely be broken down for internal cleaning as oils and other food particles seeped in through the ceramic. Given the varying sizes of equipment and the different cooking requirements, the need for different sized burners arose. We took their 9 SKUs of burner sizes and shrunk it down to 4 simple sizes. A 6”, 8”, 10” and 16/8” burner, these burners were designed to be modular, interchangeable and scalable. The smallest 6 inch burner would be used in small kitchens and for Chinese dishes, as the quantity of food required increases so does the burner size. The burners can be stacked alongside each other to save space and also create larger scales with repeating modules. For eg, in a 2x2 grid of 6” burners effectively gives you a 12 inch squared surface this works for the 8 and 10 inches as well to give you a 16 and 20 inch burner. These larger sizes are used for bulk cooking and the 16/8” is used in hot plates and bratt pans The mounting system for these burners was also devised as such to allow for easy replacement and maintenance. It was also designed to be universal so we can reduce custom parts wherever possible and streamline manufacturing. The burners themselves were built in a sandwich form factor allowing them to be easily serviced by the removal of 4 screws. We worked on the Industrial Design refining the shape to be seamless and sculpted with a better choice of material thus reducing the overall weight of the part but also increasing the tensile strength. We created and designed an architecture where damaged parts are easy to replace, due to the extreme conditions of the commercial kitchen. With a cooler finish and texture, we completely redesigned the finish and thus helped in increasing efficiency further than what they had achieved.